The production and manipulation of graphene usually requires two separate processes for industrial application. The aggregation of graphene is a problem during its manipulation, and this can sometimes hinder the applications of graphene. Reporting in Nanotechnology, Daoheng Sun’s team from Xiamen University demonstrate the successful integration of the production and manipulation of graphene into a one-step cost-effective process.

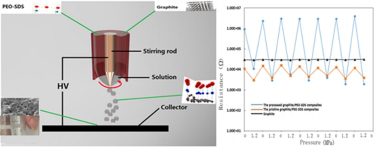

Direct exfoliation of graphite by PEO-SDS and pressure dependence of the resistance of the pristine graphite/PEO-SDS composites

The rapid production and accurate deposition of graphene composites are driven by the strong interaction between the polymer bond with sodium dodecyl sulfonate (SDS) and graphene in water. In a pseudoplastic fluid, graphite flakes undergo a shear force and a centripetal force arising from the rotating rod. At the same time, the microchannel can also increase the shearing time to enhance the interaction between polymer-SDS and graphene. Then exfoliation arising from the interplay between the centripetal and shear forces occurs in the microchannel between the nozzle and the stirring rod.

The one-step process to manipulate graphene

In addition, the polymer-SDS fluid climbs the rod due to the Weissenberg effect. This deposits graphene composites directly onto the substrate under a strong electrical field. It should be noted that the Weissenberg effect “chooses” the polymer-SDS fluid with the graphene and transports them to the needle tip which is of benefit to accurately deposit via a strong electrical field.

Dr Shihu Wang and his advisor Professor Daoheng Sun

The researchers can therefore directly deposit micro-scale patterns of graphene/PEO-SDS composites on flexible substrates to construct flexible electronic devices. Interestingly, the pattern of graphene/PEO-SDS composites exhibited a very high sensitivity to the pressure. And the SEM images of this materials show a porous construction.

More information about this research can be found in the journal Nanotechnology 27 31LT01.

Further reading

Graphene nanoplatelets self-assemble into electrical contacts (May 2016)

Surprising current domains of misoriented graphene on graphite (Mar 2015)

Can atomic force microscopy really measure the thickness of graphene? (Mar 2016)

About the author

Shihu Wang is a PhD student from the Institute of Non-silicon Micro-nano System Manufacturing Technology of Xiamen University. As the group leader, Professor Sun, who guided the work as the corresponding author, is interested especially in M/NEMS, Flexible Electronics, Micro/Nano Systems Manufacturing Technology, Nanofibers and Applications.

School of Aerospace

School of Aerospace  School of Aerospace

School of Aerospace